WHAT IS THE DIFFERENCE BETWEEN FUSION FORM AND FLEX-TUNED SADDLE BASES?

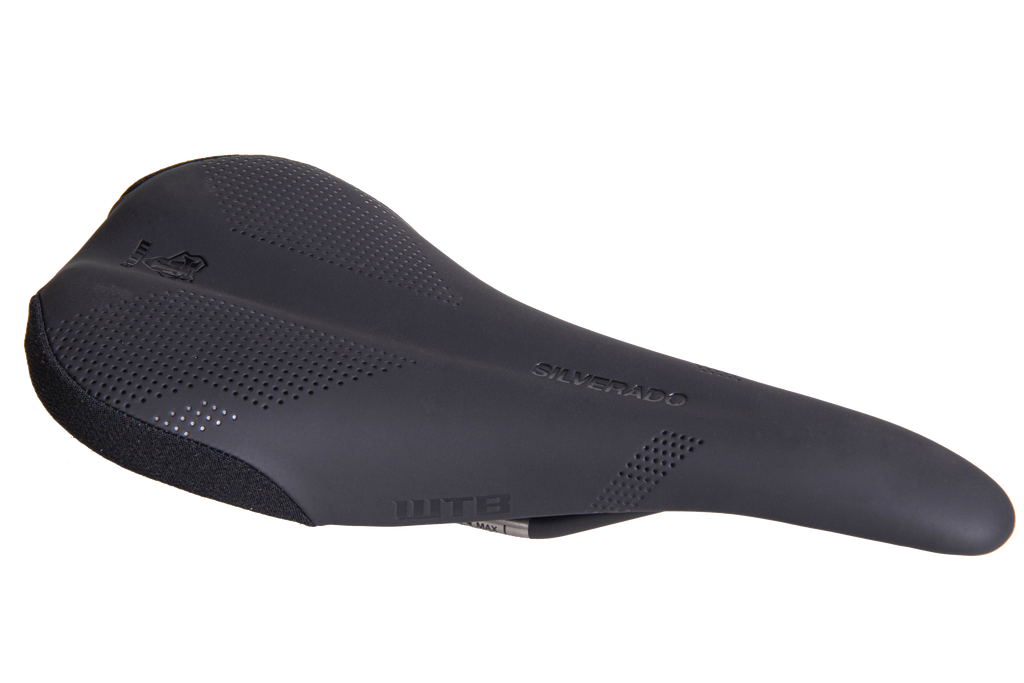

Fusion Form base technology allows us to fine-tune the amount of fiber infused into the nylon base of each specific saddle model to create a flex profile that balances comfort, support and durability to match the intended use of each individual saddle. Fusion Form also allows the padding to be recessed into the base, which provides a sleek, modern aesthetic without actually reducing overall padding thickness or affecting comfort.

The Flex-Tuned base featured on most WTB saddles over the last decade utilizes a singular base profile to optimize comfort and support on all sad. All saddles with a Flex-Tuned base are made using the traditional "wrapped-and-stapled" method of saddle construction where the microfiber is stretched over the padding and then stapled to the underside of the saddle base. This makes the saddle appear more pillowy, although comparable saddle models share the same amount of padding thickness between Fusion Form or Flex-Tuned versions.

IS THINNER OR THICKER PADDING BETTER FOR ME?

Thinner padding tends to be preferred by riders with good flexibility who are leaned forward while pedaling for rides longer than two hours. Thicker padding is often better for riders who sit in a more upright position and find themselves on rides that usually involve less than two hours of riding.

Thicker padding allows a rider's sit bones to sink into the saddle for a more cradled feel that feels plush and maximizes comfort for short durations of time. However, this same support can also pinch the soft tissues around your sit bones after a bit of time and end up causing more discomfort on lengthy rides. Saddles with thinner padding provide less cushion, are therefore firmer, and allow the sit bones to sit perched atop the saddle rather than cradled within it. While thinner padding may seem less comfortable at first, it often proves more comfortable for rides longer than two hours.

WHAT IS THE MAX RIDER WEIGHT FOR WTB SADDLES?

Our saddles don't have a specific weight limit. The reason being that rider weight is not what limits a saddle's strength. It's the amount of force that a rider (or the ground during a crash) exerts on the saddle that determines whether it will be damaged. It's hard to put a max rider weight limit on a saddle when a 350-pound rider may not encounter any saddle strength issues while a 120-pound rider may accidentally come down too hard on the saddle and damage it. The amount of force is a bigger factor, as well as where the force is directed on the saddle. Instead, we rely on ISO testing standards to ensure our saddles are strong enough to withstand the forces exerted in most riding situations within the intended usage. All WTB saddles meet or exceed the ISO saddle standard, which is 400 kN in a downward direction on the tail of the saddle.

WHICH SADDLE RAIL MATERIAL IS THE STRONGEST? WHAT ARE THE DIFFERENT RIDE CHARACTERISTICS?

Heavier riders will exert more force on their saddle compared to a lighter rider if the rider is traveling at the same rate of speed during the point of contact. Cromoly and steel saddle rails tend to be more resilient and provide increased sheer strength over titanium or carbon rails, therefore heavier riders may find more peace of mind on a saddle with cromoly or steel rails.

All properly manufactured saddle rails should be able to handle the weight of riders well over 100kg, but how those materials fail when stressed to their limits would be my biggest consideration when suggesting a saddle that will be used by a heavier rider. Steel tends to bend, whereas titanium tends to shear and carbon tends to crack/snap. Heavier riders will likely find the most peace of mind on a saddle with steel or cromoly steel (lighter weight, yet still strong) rails.

WHICH WIDTH OF SADDLE IS BEST FOR ME?

Close x